Engineering Excellence

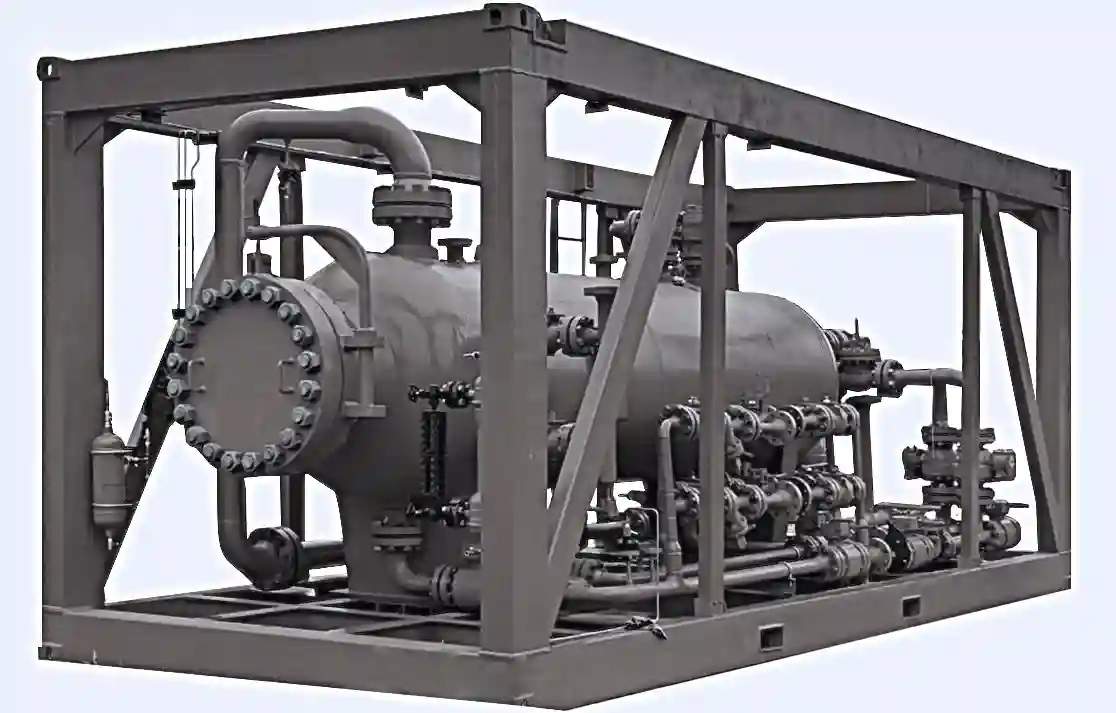

Two-Phase Pressure Vessels

A Two-Phase Separator is a critical pressure vessel used to separate a well stream into liquid and gas phases. At Ganesh Filter, we design these vessels to handle high-pressure environments while ensuring maximum output purity.

- Internal Deflectors: High-impact inlet diverters for initial separation.

- Mist Extractors: Advanced mesh pads to capture fine liquid droplets.

- Configurable Design: Available in Horizontal and Vertical orientations.

- Corrosion Protection: Internal epoxy coating for long-lasting durability.

| Design Standard | ASME Section VIII Div 1 |

|---|---|

| Material Options | Carbon Steel, SS 316L, Duplex Steel |

| Pressure Rating | Up to 1500 PSI (Customizable) |

| Testing | Hydrostatic, Radiography, NDT |