How Heatless Dryers Work

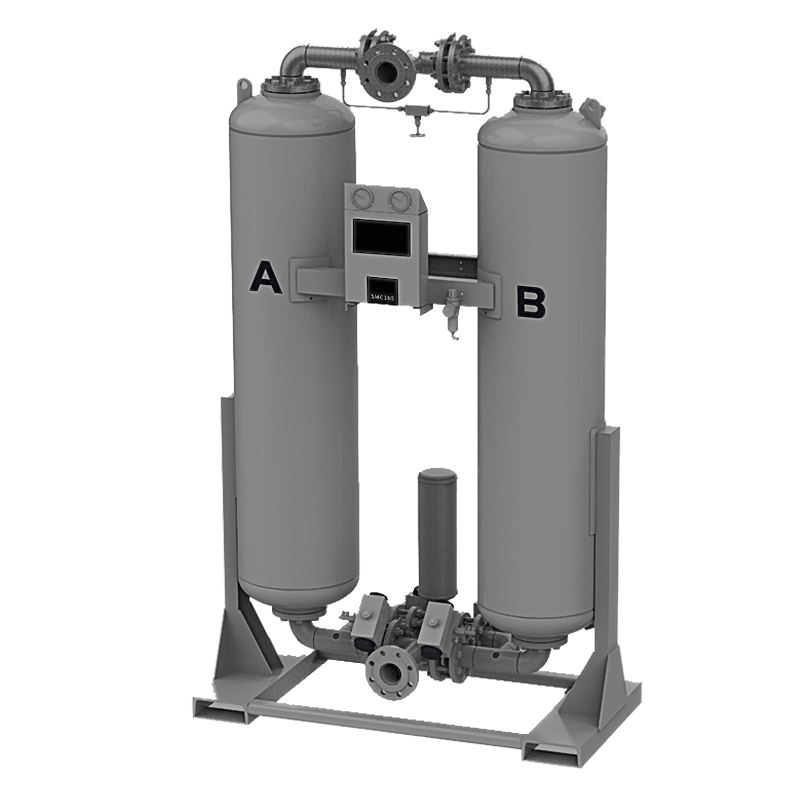

Ganesh Filter's Heatless Desiccant Dryers use two towers filled with Activated Alumina or Molecular Sieve. While one tower dries the compressed air, the other tower regenerates using a small portion of dry purge air. This continuous cycle ensures a constant supply of ultra-dry air.

| Pressure Dew Point | -40°C (Standard) up to -70°C |

| Desiccant Material | Activated Alumina / Molecular Sieve |

| Cycle Time | 10 Minutes (Fixed or Adjustable) |

| Operating Pressure | 5 to 12.5 kg/cm² |

| Control System | Microprocessor Based Automatic |

Twin Tower Adsorption Dryer System.

Key Benefits of Desiccant Dryers

Sub-Zero Dryness

Provides air dryness levels (up to -70°C) that standard refrigerated dryers simply cannot reach, ideal for critical air lines.

No Moving Parts

Simple design with high-quality pneumatically operated valves reduces wear, tear, and long-term maintenance costs.

Long Desiccant Life

Carefully selected high-crush strength desiccant beads ensure efficient moisture adsorption for several years of operation.

Protect Your Critical Equipment

Prevent moisture-related failures and corrosion in your pneumatic systems with Ganesh Filter technology.

Get a Custom Quote Today